How to Choose the right industrial glue ?

A glue is a liquid or pasty product that allows parts to be joined together. Widely used to assemble parts in the electronics, automotive, aerospace, packaging, construction, wood, appliance, textile and footwear industries, these adhesives are generally synthetic. Among the most commonly used adhesives in the industry are epoxy adhesives, cyanoacrylate adhesives and polyurethane adhesives.

A glue is a liquid or pasty product that allows parts to be joined together. Widely used to assemble parts in the electronics, automotive, aerospace, packaging, construction, wood, appliance, textile and footwear industries, these adhesives are generally synthetic. Among the most commonly used adhesives in the industry are epoxy adhesives, cyanoacrylate adhesives and polyurethane adhesives.  How to choose an industrial adhesive?

How to choose an industrial adhesive?

- In order to choose the right adhesive for you, you must first check if it is compatible with the materials you need to assemble.

- You will also have to take into account surrounding conditions such as ambient temperature (minimum and maximum), humidity, UV exposure, exposure to chemicals such as detergents or acids, as well as dust, which could affect the quality of the bond.

- You will also need to check that the adhesive chosen is compatible with the stresses to which it will be subjected (permanent load, vibration, shock, shear, bending, etc.) and in particular its peel strength (tensile strength).

- You should also consider whether what you are assembling should be able to be disassembled or not, and if so, how the adhesive should be dissolved.

- You should also take into account the working time, i.e. the time during which it is possible to change the position of the elements you are gluing together, and the final setting time, i.e. the time you will have to wait before the assembly can be used under normal conditions. As a rule, two-component adhesives have a shorter working time and final setting time than one-component adhesives. Cyanoacrylate adhesive, which has a setting time of a few seconds, is the exception which confirms the rule.

- Finally, you should check that the adhesive you choose complies with the standards to which the assembly is subject.

When should an epoxy adhesive be used?

When should an epoxy adhesive be used?

You can use an epoxy adhesive if you need an adhesive that provides high mechanical strength, whether in terms of impact, shear or peel.

Epoxy adhesives are available in one- or two-component formats.

Epoxy adhesives can be classified into three types based on their main characteristics after curing :

- Rigid adhesives, which offer good shear resistance and very good durability. These adhesives are used especially with rigid substrates and high static loads.

- Soft (flexible) adhesives offer good impact and peel resistance, as well as good low temperature resistance. These adhesives are especially used to bond different materials that do not have the same coefficient of expansion.

- Strong adhesives combine the qualities of rigid and flexible adhesives.

When should acrylic adhesive be used?

Acrylic adhesives are mainly used to bond various materials such as plastic, glass or wood to metal. They offer good mechanical resistance, but not as good as epoxy adhesives. However, acrylic adhesives are generally less expensive than epoxy adhesives.

The curing time of one-component acrylic adhesives is relatively long, about 5 to 30 minutes, but it can be accelerated by heating.

When should a polyurethane or urethane adhesive be used?

Polyurethane adhesives are widely used in the construction industry, for example for bonding insulation boards. They are very flexible adhesives, but offer limited mechanical strength compared to epoxy adhesives, especially at high ambient temperatures.

One-component polyurethane adhesives cure by reacting with ambient humidity. They can be applied with a heat gun to reduce the curing time. If the humidity level is low, it is preferable to use a two-component polyurethane adhesive.

Urethane-based adhesives are mainly used to bond or repair rubber-based materials, such as diving suits.

When should Cyanoacrylate Adhesive be used?

Cyanoacrylate Adhesives come in liquid or gel form. These adhesives are primarily designed for fast bonding and offer good shear resistance. At room temperature, the setting is almost instantaneous.

Liquid adhesives can be applied to parts to be joined by infiltration, they diffuse by capillary action. On the other hand, gels are particularly suitable for vertical surfaces and porous materials.

Cyanoacrylate Adhesive only adheres to a surface if there is moisture. Thus, if a surface is completely dry, it will not be effective because it will not form an adhesion. To solve this problem, you can apply a thin layer of water to the surface to start the curing process.

Cyanoacrylate adhesives are used to bond metal, fiberglass, ceramic, cardboard, rubber and plastic components. Note that for heat-resistant plastics, it is preferable to use an epoxy resin.

The disadvantage of these adhesives is that they have low impact strength and low resistance to high temperatures.

When should a silicone adhesive be used?

When should a silicone adhesive be used?

Silicone adhesives are flexible adhesives that offer high resistance to dynamic stress and good sealing properties. They also have good resistance to solvents, UV and high temperatures. However, their mechanical resistance is not very high.

Single-component silicone adhesives require high humidity to cure. If humidity is low, a two-component adhesive is preferable.

When should a two-component adhesive be used?

Irrespective of the type of adhesive, two-component adhesives have the advantage that they are not dependent on the surrounding conditions for curing and their curing time is well controlled as long as the mixture is correctly dosed.

Mixing can be done manually or automatically with the cartridge nozzle. If you mix manually, it is necessary to dose each component correctly. Some two-component adhesives can generate more or less harmful gas emissions, so it is preferable to use them in well-ventilated areas.

Do you need advice on choosing your product? Call our specialists at +32 (0)4 224 99 99, from Monday to Friday from 8:30 am to 5:00 pm.

Best-selling glues

3M 77 Scotch-Weld Spray - Multipurpose aerosol glue - Clear - 500 ml -

Item No. 10000412

€ 21,94

Add to cart

3M DP 490 Scotch-Weld Structural Epoxy Adhesive - Black - 50 ml - Per box of 12 cartridges

Item No. 10001606

€ 37,54

Add to cart

3M 1201 Silicone Resin in 100 gr tube - white - By Box of 12 tubes

Item No. 11300180

€ 25,88

Add to cart

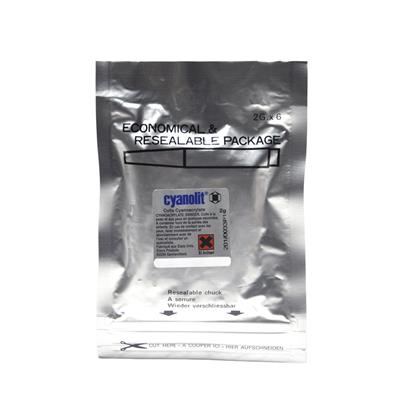

Cyanolit 202 Alu Pouch 6 x2 g - Cyanoacrylate Adhesives - Transparent - By bag of 1 piece

Item No. 13110111

€ 13,29

Add to cart

How to

How to  When

When When

When