How to choose your masking tape ?

There is no single solution for all applications. Each tape is designed for a specific application. Here is a brief overview of some of the criteria to consider each time you choose a masking tape:

There is no single solution for all applications. Each tape is designed for a specific application. Here is a brief overview of some of the criteria to consider each time you choose a masking tape:  Tape strength

Tape strength

Resistance simply refers to how long the tape will remain in place on the surface once it is applied. For best results, you should choose a tape with a higher resistance so that it will stay in place longer and will not come off easily. You should also consider whether the tape will be exposed to sunlight or heat during application, as these factors may affect the resistance. Removal in one piece

For masking tape, the application is not permanent and at some point you will have to remove it. In most cases, tapes can leave a residue on the surface, which is not desirable. When choosing your tape, be sure to choose one that can be removed so that the surface remains clean.Tape Compliance

The tape you choose must be able to adapt to the deformations that may occur depending on the application you will use it for. For example, if you are going to use the masking tape on a surface with many curves, it must be of sufficient quality so that it does not crack or break when applied to curved parts. Main masking tapes :

Main masking tapes :

General Purpose Masking Tape

These tapes are usually made from cream-colored crepe paper and are available in various widths. They use a rubber-based adhesive and are best suited for applications such as short term painting and decorating jobs. They can generally withstand temperatures between 30 - 70℃ depending on the brand of the tape.The disadvantage of these tapes is that they can damage the applied paint if left in place for too long (24 to 48 hours) and can leave a residue on the surface when removed. In addition, their textured crepe paper structure lets the fluid paint flow under the tape, resulting in a not always optimal rendering.

High temperature masking tape

In general, the temperature resistance of these tapes is due to the latex saturation level of the crepe paper and the use of a silicone adhesive that can withstand higher temperatures. Like the general purpose version, these tapes will not give you a clean line but can be used for body repair and powder coating applications where the substrate must pass through a curing oven. There is a range of specific powder coating tapes available made from temperature resistant polyester up to 220℃.Low-tack Masking Tape

If you are looking for a tape to apply to a freshly painted surface, the best solution is to use a low-tack tape. They have an adhesive designed to be less aggressive than general purpose masking tapes. They can be removed from delicate surfaces without damaging the surface or leaving residue. Sharp Edge Masking Tape

Sharp Edge Masking Tape

Sharp Edge masking tape is the ideal solution for most painters and decorators because it provides a clean line when painting. Most precision tapes are available in a variety of widths and adhesion levels, including low-adhesion and outdoor use. Outdoor Masking Tape

Designed for outdoor use, they are UV and moisture resistant and will not deteriorate in sunlight or wet conditions. They also use a different type of adhesive and are generally thicker, allowing them to stick to more uneven surfaces.There are other variations of tapes designed for use in plastering or rendering or resistant to certain alkaline solutions and low-concentrated acids.

Do you need advice on choosing your product? Call our specialists at +32 (0)4 224 99 99, from Monday to Friday from 8:30 am to 5:00 pm.

Best-selling masking tapes

Polymask SG 5038A Surface Protection Film - Clear - 625 mm x 350 m x 0.05 mm - per 2 rolls

Item No. 10000595

€ 340,99

Add to cart

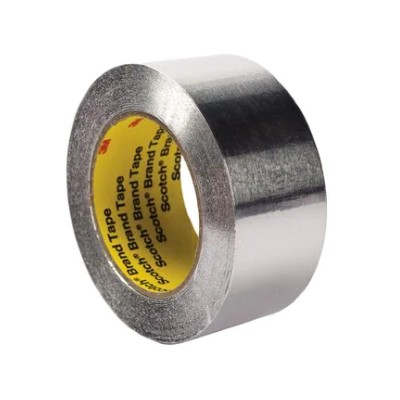

3M 425 Aluminium Metallic Tape - Grey - 25 mm x 55 m x 0.12 mm - Per box of 36 rolls

Item No. 11103705

€ 45,37

Add to cart

€ 90,74

Add to cart

3M DT11 Heavy duty duct tape - Silver - 48 mm x 55 m x 0.28 mm - Per box of 24 rolls

Item No. N0379040

€ 20,00

Add to cart

Tape

Tape  Main

Main  Sharp Edge

Sharp Edge