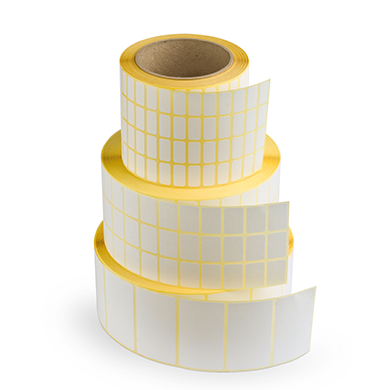

How to choose your roll labels?

Selecting the right labels for your printer is essential to ensure accountability, high performance and maximum print quality. Etilux offers a wide range of labels for direct thermal and thermal transfer printers, compatible with barcode printers available on the market.

Selecting the right labels for your printer is essential to ensure accountability, high performance and maximum print quality. Etilux offers a wide range of labels for direct thermal and thermal transfer printers, compatible with barcode printers available on the market.  Discover our range of labels on rolls

Discover our range of labels on rolls - Direct or thermal transfer labels

- Paper or synthetic labels

- Low and high temperature labels

- Blank and pre-printed labels

- Permanent and repositionable adhesive labels (standard or specific adhesives)

- Non-adhesive labels

- Special labels (water-soluble, for marking textiles, for jewelry, for tires, security...)

- Cash register receipts

We can also supply your pre-printed labels on request.

How to choose?

How to choose?

There are currently thousands of possible uses for labels. Even if it sounds simple, it can be difficult to find the right labels. Here are a few tips for choosing your labels on a roll : TT vs DT

These are two very different technologies.Direct Thermal (DT)

In this process, thermal paper (paper with a thermal layer) is used and printing is done by heating the thermal head. This process is mainly used when labels have to be preserved for a relatively short period of time, for example, shipping labels.Thermal Transfer (TT)

In contrast to direct thermal printing, an ink ribbon is required for thermal transfer printing. The ink is transferred from the ribbon to the label to be printed by heating the print head.This method is superior to direct thermal printing. This technology allows printing not only on normal paper but also on synthetic materials (polyethylene, polypropylene, vinyl, polyester, etc.).

This method is suitable for warehouses where raw materials are stored for long periods of time or extreme production environments, such as the chemical, pharmaceutical, automotive, etc. sectors.

The material

The material

There are 2 main categories: paper labels (vellum paper, recycled paper...) and synthetic labels (polypropylene, polyester, PVC...), which are more durable than the first ones. The adhesive

The adhesive of a self-adhesive label allows the label to stick; this is the sticky part of the label. The adhesive attaches your label to the surface to which you are going to apply it. Adhesives are generally appreciated according to their adhesion or tack and the applications you want to use them for: permanent labeling, removable labeling, special freezer labeling. The direction of exit

The direction of exit

Depending on the printer you are using, the direction of the label output may be different. The exit direction, or rewind direction, refers to the position in which a label is on the roll as it unwinds. There are two output directions: inside and outside.

Therefore, it is important to know the rewind direction of your labels so that they are properly positioned for optimal application.

In any case, it is imperative that you ask yourself these two questions:

- On which surface (flexible, rigid, flat...) and for what length of time should the label be applied?

- In what environment and under what conditions will the label be used? (inside, outside, humidity, hot / cold...)

How to

How to  The

The  The direction of exit

The direction of exit